What Is Sashimi- or Sushi-Grade Fish? A Detailed Guide

For the preparation of sushi or sashimi, the quality and freshness of raw fish and seafood are critical. This guide explains the requirements for the safe consumption of raw fish and seafood.

This guide provides carefully researched information to clarify what the terms sushi-grade and sashimi-grade actually mean.

Table of Contents

What Does “Sushi- or Sashimi-Grade” Mean?

The terms sushi-grade and sashimi-grade are commonly used to describe fish or seafood intended for raw consumption. Although these designations may appear authoritative, they are neither legally defined nor standardized. In practice, they function primarily as widely accepted marketing terms used to guide consumer choice or to promote specific fishery products.

When you see seafood with this designation, it simply means that the seller has decided the fish is likely suitable for sushi; based on an assessment of bacterial levels, temperature, parasites, appearance, smell, taste, presentation, and time since catch.

Nick Sakagami, Osakana-Master [1]

Consequently, many commercially available fish or seafood are suitable for the preparation of sushi or sashimi, provided they meet certain quality and safety criteria. In many countries, food safety regulations apply to fish and seafood intended for raw consumption. These regulations do not define ‘sushi-grade’ or ‘sashimi-grade’, but specify hygiene, cold-chain management, and parasite control requirements. These regulations dictate how fish or seafood must be handled if intended for raw consumption by consumers. Specifically, these rules typically address the maintenance of the necessary cold chain, hygiene, and the targeted elimination of parasites potentially harmful to humans. The preparation of sushi or sashimi is only one of many possible raw dishes. Therefore, the relevant regulations focus on food safety rather than qualitative (organoleptic) characteristics such as taste, appearance, smell, and color. Nevertheless, these characteristics, along with freshness and safety, play a central role in the selection of ingredients for the preparation of sushi and sashimi.

The following sections will explain the fundamental requirements for the general definition of sushi- or sashimi-grade. Since sushi has long become a global culinary phenomenon, consumers often encounter this terminology at the fishmonger’s counter, in supermarkets, or in various online retail shops. It is important to note that the term sushi- or sashimi-grade generally refers to compliance with minimum food safety requirements for raw consumption, not to sensory or gastronomic quality. The quality range of suitable and “safe” ingredients thus spans from affordable mass-market products to high-priced premium items.

Fundamentals of quality

Non-disclosed author. All rights reserved ©

Taste is subjective, whereas food quality can be assessed using objective criteria such as freshness, handling, hygiene, and chemical and microbiological parameters. For an optimal taste experience when consuming sushi or sashimi, the raw ingredients should therefore be of very high quality. Exceptions are fish that have been aged to enhance flavor. During controlled aging, certain physicochemical parameters change due to enzymatic processes. While shelf-life decreases, flavor complexity and tenderness may increase when aging is properly managed.

Regardless of whether you prefer fatty fish like salmon or lean fish like sea bass, the better the quality, the tastier the final dish. Therefore, from the consumer’s perspective, it is important to distinguish between high-quality and lesser-quality raw ingredients. The origin and seasonality are also crucial, especially for wild-caught species. Climatic influences and spawning times significantly impact general physiology and fat content, thus directly affecting the taste.[2] [3] The price is not necessarily an indicator of quality or good taste. However, it is often observed that quality and good taste come with a higher price. Experience shows that farmed fish from high-quality aquaculture facilities are superior in taste to those from ordinary aquaculture, especially when intended for sushi or sashimi. Products from facilities that focus on low stocking density, gentle handling, feed composition, and special slaughter methods (e.g., ike-jime) have a distinct advantage.

Most wild fish species available in the broader market predominantly come from commercial or industrial fishing. The possible fishing methods range from rod and line to kilometer-long trawl nets. Fundamentally, any fishing method can be used to offer fish in sushi- or sashimi-grade quality. However, the fishing method can indeed be responsible for the difference between top and standard quality.[4] The more desirable a species is, the more likely it is that the fishing methods will be differentiated with regard to quality, as in the case of tuna.

“Freshness” as the Foundation of Sushi and Sashimi

Nunawwoofy. Fresh fish on ice at the fish market . All rights reserved ©

The freshness of fish and seafood is crucial when preparing sushi and sashimi. In the context of food, ‘freshness’ refers to a state in which the original properties of an ingredient are largely preserved.[5] This is particularly important for dishes like sushi and sashimi, which rely on the quality and integrity of raw marine products. Fish and seafood are exceptionally perishable compared to other foods and therefore require special care in their handling. After the death of fish or seafood, proteins and fats are broken down by enzymes, leading to changes in texture and flavor. Simultaneously, bacterial growth accelerates, posing health risks when consumed raw.

To preserve freshness, fish for sushi or sashimi is rapidly chilled immediately after being caught and then stored at precisely controlled temperatures just above the freezing point. This slows bacterial growth without forming ice crystals that could damage the delicate flesh. Spoilage thus serves as an indicator of undesirable changes after catch or slaughter, directly impacting the quality and safety of the final product.

For certain species, particularly tuna (maguro), bastard halibut (hirame), and mackerel (saba), controlled aging can be used to enhance flavor and texture.[6] This process is carefully monitored and always begins with fresh fish. Aging breaks down specific compounds, resulting in a more complex flavor profile and tender texture. However, it requires expertise to prevent spoilage. Even for ingredients requiring some aging, high initial freshness is crucial for optimal flavor development and safe consumption.

The chef’s ability to assess and maintain the freshness of ingredients for sushi and sashimi is crucial. This involves not only proper storage and handling but also the skill to evaluate ingredients based on sensory characteristics such as smell, color, and firmness.

What Safety Measures Are Important in the Preparation of Sushi and Sashimi

Spoilage – Minimizing Microbial Risks by Preserving Freshness

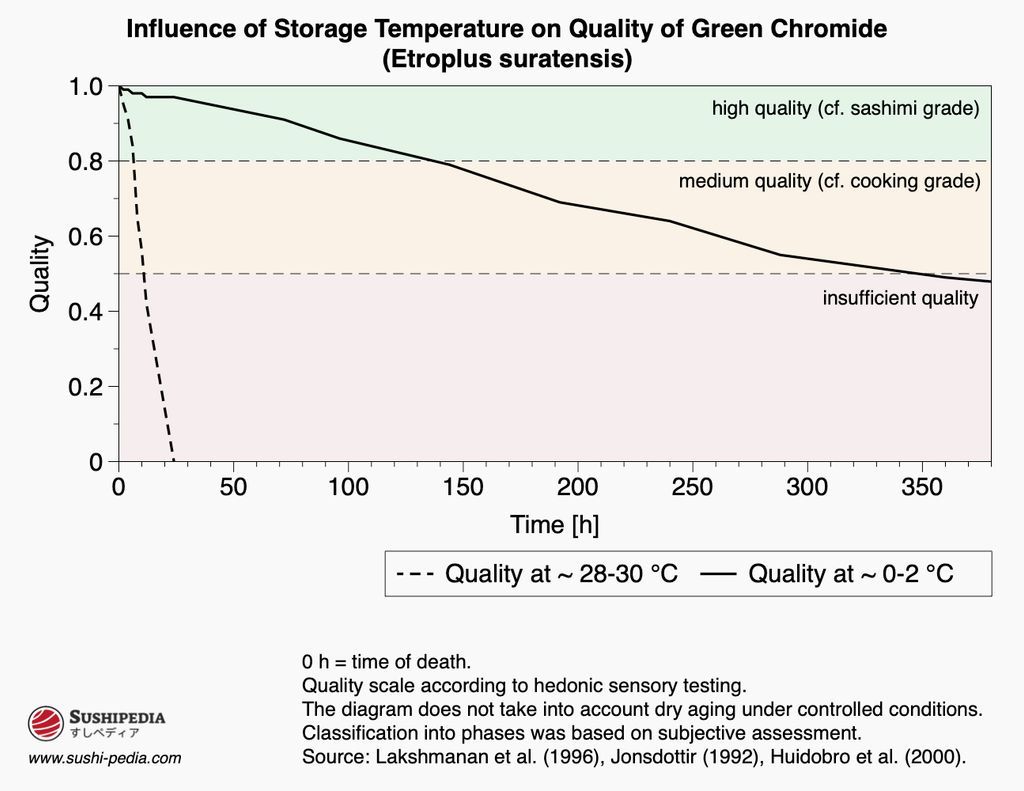

SushiPedia. Influence of storage temperature on the quality of striped tilapia. All rights reserved ©

Raw fish and seafood are considered particularly sensitive foods from a microbiological and hygienic perspective. The spoilage process is triggered by the action of enzymes, bacteria, and chemical reactions. Therefore, the longer the time since death, the more advanced the growth of potential pathogens. When using raw ingredients, a certain baseline level of microbial contamination should be assumed. Processing and preparation are expected to further increase this microbial load. This underscores the importance of freshness and the quality of the initial product, as sushi or sashimi is typically consumed raw, without prior (germicidal) heating.

The spoilage process typically involves changes in the physical properties of the raw material. These changes result in a deterioration of food quality, such as color, texture, and taste. While both freezing and cooling extend the shelf life of food, the objective quality of the food continues to decline regardless of the preservation method.[7] Therefore, fish and seafood should be as fresh as possible, whether they are processed into sushi or sashimi or stored.

Preservation by Freezing

Non-disclosed author. Octopus in ice in plastic box. All rights reserved ©

In everyday life, the term “freshness” is occasionally applied to indicate the recentness of the catch of fish. This is usually interpreted to mean that the product has not been and is not frozen. However, freezing fish or seafood does not restore freshness, but helps to preserve the existing level of freshness at the time of freezing. It is important to note that while freezing extends the shelf life of food, it inevitably leads to a deterioration in food quality.[7] The quality loss is significantly influenced by the freezing technology used.

Properly and industrially frozen fish or seafood, unlike catch-fresh products, have the advantage of significantly longer storage times. Freezing is one of the most effective forms of food preservation. Pathogens that cause food spoilage are deactivated at sufficiently low temperatures (starting at -18 °C). The use of industrial flash freezing minimizes the deterioration of food quality.[8] Fish or seafood preserved by flash freezing immediately after catch thus provide adequate and qualitatively satisfactory ingredients for the preparation of sushi or sashimi.

Minimal Quality Loss With Shock Freezing

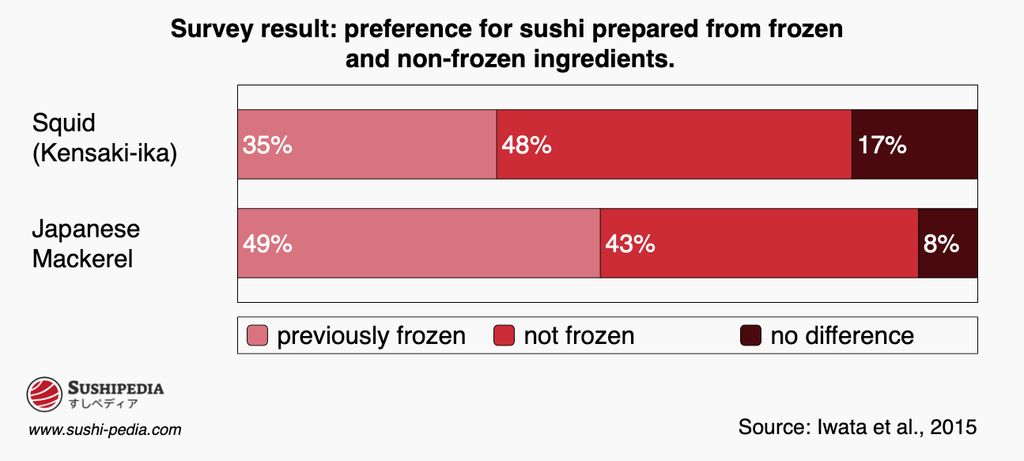

SushiPedia. Preference for sushi made from frozen and non-frozen ingredients. All rights reserved ©

The quality of frozen foods is often perceived to be inferior to that of “fresh products”, which are typically defined as items that have been recently caught or harvested. From an organoleptic point of view, fresh products that are properly chilled and consumed promptly are not significantly inferior and even have advantages in terms of handling. Frozen foods often have a reputation for being inferior to fresh products, primarily due to differences in texture, flavor, and appearance that can occur during the freezing and thawing process. From an organoleptic perspective, which involves the sensory evaluation of food (including taste, sight, smell, and texture), properly chilled, unfrozen products consumed shortly after catch may retain certain sensory properties, whereas industrial flash freezing can preserve quality very effectively when immediate consumption is not feasible.

Freezing, especially slow freezing, can negatively alter the textural properties of products. However, flash freezing better preserves these properties, making the differences compared to fresh products very small or sometimes imperceptible. The very short freezing process in flash freezing forms only very small ice crystals in the cell fluid, keeping the cell structures intact. The degree of cellular damage is directly related to food quality in terms of taste, texture, nutritional value, and appearance.[9] Modern methods enable the preservation of fish and seafood without significantly deteriorating their sensory properties or nutritional value. They serve as a convenient alternative to recently caught or harvested products when such ingredients are unavailable or impractical to utilize.

Hygiene – Prevention of Cross-Contamination

Strict hygiene measures are of paramount importance in the preparation of sushi and sashimi to ensure both the safety and quality of the dishes.[10] The process begins with the careful selection of fresh and high-quality ingredients, with particular attention to the freshness and origin of fish and seafood. Maintaining an unbroken cold chain from procurement to processing is essential to prevent bacterial growth. Before and continuously during preparation, work surfaces, utensils, and hands must be thoroughly cleaned to minimize the risk of cross-contamination. Although the use of disposable gloves can be advantageous, it does not replace the need for regular handwashing. Specifically, the preparation of nigiri sushi is often impractical with disposable gloves, as precise tactile feedback is required for shaping. Additionally, touching kitchen areas with contaminated gloves can result in even more severe cross-contamination. It is also resource-intensive to change gloves with every contamination, and their reuse can lead to even more unhygienic conditions.

Proper storage of ingredients at appropriate temperatures is essential to prevent the growth of bacteria and the formation of toxins. The separate storage of raw fish and other foods is crucial to prevent cross-contamination, where bacteria or viruses can be transferred from one food item to another.

For professional processors and restaurants, implementing the HACCP system (Hazard Analysis and Critical Control Points) is crucial. The specific challenges in preparing and storing sushi, such as handling raw fish and preventing cross-contamination, require comprehensive risk analysis and control. The seven basic principles of the HACCP system allow for identifying and monitoring critical control points – from procuring ingredients to preparation and presentation. Implementing and complying with HACCP when handling ingredients is essential to ensure the highest standards of food safety and quality in sushi preparation. This includes measures such as temperature control of raw ingredients, preventing cross-contamination, and ensuring hygienic work practices. Furthermore, regular training of personnel on proper food handling and processing, as well as adapting HACCP plans to new procedures, are integral parts of these efforts.

Parasites – Risk Minimization and Hazard Management

SushiPedia. Parasit im Fleisch eines Fisches für Sushi. All rights reserved ©

When consuming fresh, previously unfrozen fish or seafood raw, there is a risk that they may be contaminated with viable parasites that can be harmful to humans.[11] This is especially problematic for fish or seafood caught in the wild, as assessing the potential for parasitic infection is more challenging.

These parasites pose a significant challenge to the safety and quality of seafood, especially in the preparation of sushi and sashimi. Among the various parasites that can occur in fish and seafood, Anisakis simplex is one of the most relevant and concerning. A. simplex is a nematode parasite found in certain fish species, and it can cause anisakiasis in humans who consume infected raw or inadequately cooked fish. This parasitic infection can lead to symptoms such as nausea, vomiting, and abdominal pain.

Preventing infection by parasites requires careful preventive measures, including selecting fish from safe sources, proper processing, and specific methods to eliminate any parasites before preparing the fish for consumption.

Freezing Treatment as Protection Against Parasitic Infection

It must be ensured, especially for raw consumption, that no viable parasites are present in the meat. For example, determining parasite infestation by illuminating fillets is only partially effective. This method only detects parasites immediately under the surface, and can thus only provide information about a fraction of the total burden.[12] Epidemiological data from the source fishing areas can provide insight into the risk of possible parasite infestation, but are not an absolute guarantee for the absence of parasites in wild fish.[13][14] According to regulation EC 1276/2011 [15] of the European Union, the following core temperatures and storage conditions must be met to kill nematodes; otherwise, fish or seafood is not approved for raw consumption unless there are exceptional conditions.

- Freeze at min. −20 °C until solid. Store at min. −20 °C for 24 hours; or

- Freeze at min. −35 °C until solid. Store at min. −35 °C for 15 hours.

The regulations of the US Food and Drug Administration (FDA) go even further and prescribe:[16]

- Freeze at min. −20 °C until solid. Store at min. −20 °C for 7 days; or

- Freeze at min. −35 °C until solid. Store at min. −35 °C for 15 hours; or

- Freeze at min. −35 °C until solid. Store at min. −20 °C for 24 hours

Most household appliances are not capable of maintaining a continuous temperature of at least -20 °C. Additionally, the study by Podolska et al. (2019) shows that the speed of the freezing process should be considered, and extended storage times should be taken into account.[17] The study by Sanchez-Alonso et al. (2018) suggests that domestic freezers, which operate with low cooling capacity and uneven temperature distribution, may not reliably ensure the complete inactivation of Anisakis larvae. This presents a potential health risk.[18]

When Can Freezing Treatment Be Exempted?

Non-disclosed author. Aquaculture in Mediterranean sea. All rights reserved ©

If fish or seafood come from aquaculture, the mandatory freezing treatment for raw consumption according to EU regulation can be waived under certain conditions. For safe consumption, the following conditions must be met according to this EU regulation:[15]

- Use only animals reared from embryos

- Feed Free of Viable Parasites

- The animals must be raised in an environment that is epidemiologically proven to be free of parasites.

However, if the aquaculture operation uses officially approved procedures that ensure that no viable parasites are present in the products and therefore pose no risk to health, this obligation can be waived.

Farmed fish and seafood raised in land-based tanks or closed recirculating systems and fed with suitable feed are considered relatively safe regarding the presence of parasites that pose a health risk. This is contingent upon the condition that the farmed animals are raised from embryos and not taken from the wild, and that the water supply is demonstrably free of parasites.

The European Commission indicates that the parasite-killing freezing treatment of wild-caught fish can be waived if epidemiological data suggest that the fishing grounds of origin do not pose a health risk regarding the presence of parasites, and the competent authority approves this. However, the European Food Safety Authority (EFSA) considers that, based on current knowledge, no marine fishing grounds are known to be free of Anisakis larvae.[15][19]

The U.S. Food and Drug Administration (FDA) maintains a list of species with a high risk of infestation by parasites harmful to humans but also recommends an individual assessment of the situation regarding raw consumption for species with a lower risk.[16]

According to the European Food Safety Authority (EFSA), the likelihood of parasitic infection in farmed Atlantic salmon (Salmo salar) raised in floating cages (marine aquaculture) is considered low. Apart from Atlantic salmon, there is insufficient surveillance data for other farmed species. Therefore, it is not possible to identify additional fish or seafood species from marine aquaculture that pose no health risk concerning the presence of parasites.[14][20]

Strategies for Parasite Prevention in Japan

In international comparison, particularly with regulations in the USA and Europe, Japan is characterized by a less restrictive approach to the consumption of raw fish. While strict guidelines exist in the USA and Europe that dictate the conditions under which fish for raw consumption must first be frozen to eliminate parasites like A. simplex. Japan relies primarily on non-binding recommendations and professional standards rather than mandatory freezing requirements comparable to those in the EU or USA. This approach relies both on recommendations and the expertise and diligence of the chefs.

The Japanese Ministry of Agriculture, Forestry and Fisheries and the Ministry of Health, Labor provide detailed recommendations for handling fish intended for raw consumption. These recommendations include adequately cooling, transporting, and gutting freshly purchased fish immediately. The need to quickly remove the internal organs is based on the fact that Anisakis spp. larvae mainly parasitize the surface of the organs. With decreasing freshness and progressing time, these parasites can, however, migrate into the musculature, the edible parts of the fish. Furthermore, it is recommended to consume fresh seafood that has been sufficiently frozen (at least 24 hours at –20 °C or 48 hours at –18 °C). For business operators, the Japanese Ministry of Health, Labor and Welfare provides clear instructions: The fish should be as fresh as possible and gutted immediately. The consumption of raw fish entrails should be avoided. A visual inspection and removal of Anisakis larvae is essential and is recommended, as is freezing the fish (at least 24 hours at –20 °C) or heating it (1 minute at 70 °C or higher).

The Japan Fisheries Association emphasizes that the only method to completely avoid anisakiasis is freezing or heating the fish. However, there is a discussion among professionals who emphasize that careful inspection of each fish can prevent anisakiasis.[21] At the same time, this view underscores the high importance that Japanese gastronomy places on the freshness and quality of sushi and sashimi. It reflects a preference for using the expertise and judgment of chefs to ensure the safety of the consumed fish. However, this approach is not entirely free of criticism, as it relies heavily on the individual skills and diligence of chefs. Critics argue that this could lead to inconsistent safety standards and increase the risk of anisakiasis, as not all chefs can reliably identify and remove parasites.[22][23] The prevalence of anisakiasis is closely linked to the tradition of consuming lightly cooked or raw fish or seafood, such as sushi and sashimi.[24] Despite efforts to prevent parasitic infections such as anisakiasis by freezing raw fish, the disease is still prevalent in Japan and other regions with high consumption of raw fish dishes, albeit with low prevalence.[25]

Japan's approach to raw fish consumption is based on a combination of government recommendations, expertise, and practical skills of the preparers. While strict regulations are preferred in other regions such as the USA and Europe, Japan emphasizes the importance of training and experience in handling and preparing raw fish. Nevertheless, it should be reassuring to note that trained and professionally educated chefs have a very low risk of infection. Their comprehensive training and experience enable them to effectively identify and minimize potential risks, ensuring the safety of the consumed fish. However, a very slight residual risk cannot be completely ruled out.

The Effect of Marinade on Parasites

Not all fish species are used untreated for making sushi or sashimi. For example, mackerel, Pacific herring, or young sea bream are marinated in a sour solution of salt, vinegar, soy sauce, or other ingredients. A popular Japanese method is marinating in a vinegar solution. The Japanese word for this process, 'su-jime', refers to a procedure where raw fish is sprinkled with salt, rinsed, and soaked in vinegar. First, the salt draws water from the surface of the fish through osmotic pressure and firms the protein in the fish muscle. Subsequently, the vinegar also acts on the protein and hardens it, while small bones soften. This process makes the fish firmer, imparts the flavor of salt and vinegar, and retains moisture. A popular sushi or sashimi ingredient made by this method is shime saba. Marinating produces a certain antibacterial effect, but has little impact on potentially present parasites. Although some cooking or sushi literature may encourage killing parasites by marinating, studies show that traditional marinades are ineffective and thus not an adequate alternative to freezing treatment.[26][27] An exception is the traditional German or Danish method of marinating herring fillets. However, this method requires a storage time of at least 5 to 6 weeks in an 8-9% salt solution to ensure that all parasites are killed.[28] To reliably kill parasites using a salt and vinegar solution in a short time, the pH value would need to be so low that the meat would be nearly inedible.

Summary and Conclusion

Non-disclosed author. Classic Japanese sushi with raw tuna on a white plate on a gray table. Japanese cuisine. Close up, selective focus. All rights reserved ©

Fish and seafood for sushi or sashimi must be fresh and meet the appropriate standards. Wild-caught marine and freshwater organisms can contain viable parasites that pose a risk to human health. In addition to diagnostic laboratory methods, inspection and visual examination during filleting are common methods for detecting parasite infestation. However, these visual methods are less reliable for large species or unprocessed fish and seafood, and they depend heavily on the expertise of the inspector or chef. Therefore, wild-caught fish without proper freezing treatment are rarely safe raw ingredients for sushi or sashimi. Despite traditional preferences, to ensure food safety, from a food safety perspective, industrial flash freezing is the most reliable method to minimize parasite-related risks in wild-caught fish intended for raw consumption.

Freezing treatment can be waived if it is unequivocally ensured that the ingredient is free from parasites. Farmed fish and seafood can be processed fresh into sushi or sashimi. If non-flash-frozen wild fish is used, it should be left only to experienced chefs who can thoroughly inspect it for parasites. Nonetheless, there is a slightly increased risk of parasite infestation compared to flash-frozen products. Consumers should be aware of this risk and decide whether they are willing to accept this minimal risk for authentic taste. Those who want to be absolutely safe should choose flash-frozen products, where viable parasites are reduced to a negligible level.

In addition to safety, the freshness, and quality of the ingredients play a crucial role. Fresh and properly stored ingredients ensure a better taste experience and higher food quality. Factors such as fishing methods, farming conditions, timely cooling, and proper storage ensure that the raw ingredients are both safe and of excellent taste. The combination of freshness, quality, and safe handling makes the enjoyment of sushi and sashimi a safe and high-quality culinary experience. In this sense: Itadakimasu!

Frequently Asked Questions (FAQ)

-

Is it advisable to thaw raw fish outside the refrigerator at room temperature?

In terms of both food quality and safety, it is recommended to refrain from thawing at room temperature. The larger the food to be thawed, the greater the deviations between core and surface temperature. Alternatively, the thawing process can also take place in an ice-cooled salt solution.

-

At what temperature should fish or seafood be stored?

Freshly caught or already thawed products, must be stored at a temperature between 32 °F (0 °C) and 40 °F (4.44 °C) (+4 °C). Frozen seafood should be stored at a temperature of -0 °F (ca. -18 °C) or below.

-

How long can freshly caught fish be stored on ice or at a similar temperature?

Depending on the type of fish, the possible shelf life differs significantly.[29] With this in mind, it is recommended that freshly caught (not frozen) fish should not be older than four days if it is to be consumed raw or aged or refined specifically for sushi preparation (cf. Lakshaman[30]). It usually takes one to three days for the fish or seafood to arrive at the local fishmonger. For maximum safety, it is therefore recommended to consume purchased fish or seafood for sushi or sashimi as soon as possible, preferably within a day. If you are unsure about the freshness or suitability of the fish for raw consumption, it is advisable to seek the opinion of an expert.

-

Does purchased fish need to be refrigerated when transported home?

Interruption of the cooling should be avoided until preparation. Especially with regard to the preparation of raw sushi or sashimi, continuous maintenance of the cooling temperature is important. The growth rates of pathogens are highly dependent on temperature. In most cases, their growth is very slow below 50 °F (10 °C) and relatively rapid at temperatures above ~ 68 °F (ca. 20 °C).[31] Therefore, fish or seafood should be kept as cool as possible, because depending on the ambient temperature and nature of the raw product, the critical temperature limits can be reached quickly (e.g., in a heated car). How long the raw fish can be stored without refrigeration depends on many factors. If fresh fish is not stored immediately under suitable conditions and exposed to ambient temperature even for a short period of time, it may lead to serious deterioration of fish quality.[32] It is therefore advisable to be on the safe side when it comes to pathogens and raw seafood consumption.

-

Are certain species less susceptible to parasites?

It can be said that certain species are particularly vulnerable and others less so. For example, the U.S. Food and Drug Administration (FDA) lists the most economically important species that are highly likely to be infected with parasites.[16] Scientific studies suggest that parasites (Anisakis spp.) may not be specific to an intermediate host and thus migrate from one habitat to another, depending on the seasonal and ecological availability of such intermediate hosts.[22]

-

What is the risk of being infected with parasites in a restaurant?

Sushi and sashimi prepared from fish or seafood treated according to freezing procedures required by law in the U.S. or EU carry little or no risk of becoming infected with parasites. The risk of infection from eating sushi and sashimi is higher in countries where such legal regulations are not implemented [11]. Statistically, the likelihood of anisakiasis is relative low. In 2019, only 347 cases were reported in Japan, which has a population of over 126 million [33]. Roughly, this results in an annual incidence of 3 per 1 million people. However, the number of misreported and unreported incidents is believed to be higher [34] [24].

-

Does wasabi or soy sauce have a parasite-killing effect?

No. Wasabi, soy sauce, vinegar, and other seasonings (in usual amounts) are not sufficient to kill parasites.[35]

-

I was told that tuna is generally free of parasites, is this true?

In general, some tuna carry a high risk of being infested with parasites. For example, Japan's Tokyo Metropolitan Institute of Public Health lists bigeye tuna (T. obesus) as a potential source of anisakis parasitism.[36] The U.S. Food and Drug Administration (FDA) states that longtail tuna (T. tonggol), among others, is a source of risk.[16]

-

Is bluefin tuna free of parasites?

The assessment is ambivalent as it depends on the origin. The US Food and Drug Administration states that Atlantic bluefin tuna (T. thynnus) from sea fisheries does not pose a significant risk of parasitic infection.[16] However, the available literature suggests that bluefin tuna is susceptible to anisakis infestation.[37] In addition, studies show that bluefin tuna from aquaculture, on the other hand, may well be infected with parasites harmful to humans.[38][39][40] The same applies to the Pacific bluefin tuna (T. orientalis), studies suggest that there is a certain risk of infestation with anisakis.[41] In case of doubt, a possible parasite infestation should always be assumed.

-

Is it possible to kill parasites with a household freezer?

To kill nematodes, a core temperature of -20 °C should be reached for at least 24 hours, according to official regulations. Although some commercial freezers can reach temperatures of -20 °C, in practice it is often difficult to ensure that this temperature remains constant throughout the food, especially in the core, for the required time. Many conventional freezers can only reach a temperature of -18 °C. It is important to consider the specific characteristics and technical data of the freezer in order to estimate its maximum performance. With regard to (sucking worms) trematodes, even lower temperatures are necessary.[42] In addition, the study by Podolska et al. (2019), shows that the speed of the freezing process must also be taken into account.[17] It is significant to note that not all parasites are equally sensitive to cold. Some may be more resistant and require longer or colder freezing times.

-

Which parasites are responsible for possible disease in humans?

In general, there are three main types of parasites that can be harmful to humans: roundworms (nematodes), flukes (trematodes), and tapeworms (cestodes). In particular, nematodes of the species Anisakis spp. are responsible. In addition, Clonorchis sinesis, Opisthorchis felineus and Metagonimus spp., which belong to the flukes. Tapeworms include Diphyllobothrium latum.

-

How long can prepared sushi be stored at room temperature?

This depends on the ingredients used and the specific room temperature. Some spoil more quickly, others more slowly. In general, it is not advisable to store sashimi or sushi with raw or other perishable ingredients (e.g., mayonnaise) for more than two hours at a room temperature of ~ 70 °F (ca. 21 °C) or for more than one hour at a room temperature of ~ 90 °F (ca. 32 °C).[43]

-

Isn't fish best for sushi right after it's caught?

This is a matter of personal preference. A fish that is still in rigor mortis may be more difficult to process, but it is very tasty.[30] In Japan, for example, there is a particular preference for fish prepared and consumed before rigor mortis (pre rigor) sets in (e.g., ikeuo, ikizukuri). This meat is intense in flavor and much firmer than after rigor mortis (post rigor). In contrast, some species also undergo dry aging to refine flavor and texture. Some chefs have even specialized in aging fish over a longer period of time to intensify the flavor even further.

References and Further Reading

- [1]Nick Sakagami. Sushi Master: An expert guide to sourcing, making and enjoying sushi at home. Quarry Books, Beverly. 2019

- [2]Sarower Mohammed Golam, Hasanuzzaman Abul Farah Md., Biswas Bhabananda, Abe Hiroki. Taste producing components in fish and fisheries products: A review. International Journal of Food and Fermentation Technology 2 (2). 2012

- [3]Deng‐Fwu Hwang, Tai‐Yuan Chen, Chyuan‐Yuan Shiau, Sen‐Shyong Jeng. Seasonal variations of free amino acids and nucleotide‐related compounds in the muscle of cultured Taiwanese puffer Takifugu rubripes. Fisheries Science 66 (6) 1123-1129. 2008. DOI: 10.1046/j.1444-2906.2000.00178.x.

- [4]Shinzo Satomi. Sukiyabashi Jiro. Vertical Inc., New York. 2016

- [5]Gudrun Olafsdottir, Paul Nesvadba, Corrado Di Natale, Mercedes Careche, Jörg Oehlenschläger, Soffı́a V Tryggvadóttir, Reinhard Schubring, Michael Kroeger, Karsten Heia, Margrethe Esaiassen, Antonella Macagnano, Bo M Jørgensen,. Multisensor for fish quality determination. Trends in Food Science & Technology 15 (2). 2004. DOI: 10.1016/j.tifs.2003.08.006.

- [6]魚はとれたてが本当にうまいのか - 日本経済新聞. Nikkei, 2013. Source retrieved 6/25/2024

- [7]Paul Dawson, Wesam Al-Jeddawi, Nanne Remington. Effect of Freezing on the Shelf Life of Salmon. International Journal of Food Science 2018 (340) 1-12. 2018

- [8]Kentaro Iwata, Takahiko Fukuchi, Kenichi Yoshimura. Is the Quality of Sushi Ruined by Freezing Raw Fish and Squid? A Randomized Double-Blind Trial With Sensory Evaluation Using Discrimination Testing. Clinical Infectious Diseases 60 (9) 43-48. 2015. DOI: 10.1093/cid/civ057.

- [9]Tridib Kumar Goswami. 4th International Conference on Mechanical Engineering, December 26-28, 2001, Dhaka, Bangladesh/pp. III: Cryogenic Fish Freezing: Science, Technology & Economics. 2001

- [10]Somura, Y., Nagano, M., Kimoto, K., Oda, M., Mori, K., Shinkai, T., … & Sadamasu, K.. Detection of norovirus in food samples collected during suspected food‐handler‐involved foodborne outbreaks in Tokyo. Letters in Applied Microbiology 69 (3). DOI: 10.1111/lam.13189.

- [11]Yukifumi Nawa, Christoph Hatz, Johannes Blum. Sushi Delights and Parasites: The Risk of Fishborne and Foodborne Parasitic Zoonoses in Asia. Clinical Infectious Diseases 41 (9) 1297-1303. 2005. DOI: 10.1086/496920.

- [12]Horst Karl. Comparison of detection methods for nematode larvae (Vergleich von Nachweismethoden für Nematodenlarven). Federal Research Institute for Fisheries, Hamburg (Bundesforschungsanstalt für Fischerei, Hamburg). 1988

- [13]Paolo Cipriani, Gian Luca Sbaraglia, Marialetizia Palomba, Lucilla Giulietti, Bruno Bellisario, Ivana Bušelić, Ivona Mladineo, Roberto Cheleschi, Giuseppe Nascetti, Simonetta Mattiucci. Anisakis pegreffii (Nematoda: Anisakidae) in European anchovy Engraulis encrasicolus from the Mediterranean Sea: Fishing ground as a predictor of parasite distribution. Fisheries Research 202 59-68. 2018. DOI: 10.1016/j.fishres.2017.03.020.

- [14]EFSA Panel on Biological Hazards (BIOHAZ). Scientific Opinion on risk assessment of parasites in fishery products. EFSA Journal 8 (4). 2010

- [15]European Commission. COMMISSION REGULATION (EU) No 1276/2011 of 8 December 2011 amending Annex III to Regulation (EC) No 853/2004 of the European Parliament and of the Council as regards the treatment to kill viable parasites in fishery products for human consumption. Official Journal of the European Union 54 (327). 2011

- [16]Fish and Fishery Products Hazards and Controls Guidance. U.S. Department of Health and Human Services Food and Drug Administration Center for Food Safety and Applied Nutrition. 2020

- [17]Magdalena Podolska, Bogusław Pawlikowski, Katarzyna Nadolna-Ałtyn, Joanna Pawlak, Katarzyna Komar-Szymczak, Beata Szostakowska. How effective is freezing at killing Anisakis simplex, Pseudoterranova krabbei, and P. decipiens larvae? An experimental evaluation of time-temperature conditions. Parasitology Research 118 (7). 2019

- [18]Isabel Sánchez-Alonso, Noelia Carballeda-Sangiao, Miguel González-Muñoz, Alfonso Navas, Susana C. Arcos, Angel Mendizábal, Melina Tejada, Mercedes Careche. Pathogenic potential of Anisakis L3 after freezing in domestic freezers. Food Control 84 61-69. 2018. DOI: 10.1016/j.foodcont.2017.07.010.

- [19]Biological Hazards Panel. Scientific Opinion on risk assessment of parasites in fishery products. On request from the European Commission. EFSA Journal 8 (4). 2010. DOI: 10.2903/j.efsa.2010.1543.

- [20]B. Lunestad. Absence of nematodes in farmed Atlantic salmon (Salmo salar L.) in Norway. Journal of Food Protection 66 (1) 122-124. 2003. DOI: 10.4315/0362-028X-66.1.122.

- [21]寄生虫 アニサキス プロによる見つけ方でアニサキス食中毒を防ぐ (Parasites Anisakis Preventing Anisakis Food Poisoning with Professional Finding Methods). 大日本水産会 (Japan Fishers Association)、 2021. Source retrieved 2/13/2024

- [22]Ibukun E. Aibinu, Peter M.Smooker, Andreas L.Lopata. Anisakis Nematodes in Fish and Shellfish- from infection to allergies. International Journal for Parasitology: Parasites and Wildlife 9 384-393. 2019. DOI: 10.1016/j.ijppaw.2019.04.007.

- [23]Takabayashi, T., Mochizuki, T., Otani, N., Nishiyama, K., & Ishimatsu, S. Anisakiasis presenting to the ed: clinical manifestations, time course, hematologic tests, computed tomographic findings, and treatment.. American Journal of Emergency Medicine 32 (12) 1485-1489. 2018. DOI: doi.org/10.1016/j.ajem.2014.09.010.

- [24]Hideo Yasunaga, Hiromasa Horiguchi, Kazuaki Kuwabara, Hideki Hashimoto, Shinya Matsuda. Clinical Features of Bowel Anisakiasis in Japan. The American Journal of Tropical Medicine and Hygiene 83 (1) 104-105. 2010. DOI: 10.4269/ajtmh.2010.09-0780.

- [25]Shizuma, T.. Hepatic Anisakiasis in Japan. Journal of Liver 7 (3). DOI: 10.4172/2167-0889.1000230.

- [26]Ole G. Mouritsen. Sushi: Food for the Eye, the Body and the Soul. Jepsen & Co, Copenhagen. 2006

- [27]I. Sánchez-Monsalvez, C. de Armas-Serra, J. Martínez, M. Dorado, A. Sánchez, F. Rodríguez-Caabeiro. A New Procedure for Marinating Fresh Anchovies and Ensuring the Rapid Destruction of Anisakis Larvae. Journal of Food Protection 68 (5) 1066-1072. 2005. DOI: 10.4315/0362-028x-68.5.1066.

- [28]H. Karl, A. Roepstorff, Hans Henrik Huss, B. Bloemsma. Survival of Anisakis larvae in marinated herring fillets. International Journal of Food Science and Technology 29 (6) 661-670. DOI: 10.1111/j.1365-2621.1994.tb02107.x.

- [29]Hans Henrik Huss. FAO Fisheries Technical Paper - 348, Quality and quality changes in fresh fish. The Food and Agriculture Organization of the United Nations, Rome. 1995

- [30]P.T. Lakshmanan, P.D. Antony, K. Gopakumar. Nucleotide degradation and quality changes in mullet (Liza corsula) and pearlspot (Etroplus suratensis) in ice and at ambient temperatures. Food Control 7 (6) 277-283. 1996

- [31]Barry Leonard. Fish and Fishery Products: Hazards and Controls Guidance.. DIANE Publishing. 2011

- [32]Sami A. Humaid, Mamdoh T. Jamal. The Effect of Storage Temperature (4°C, 15°C and 25°C) on The Shelf Life of Whole Marine Fish (Rastrelliger kanagurta). IOSR Journal of Environmental Science, Toxicology and Food Technology 8 (11) 46-51. 2014. DOI: 10.9790/2402-081114651.

- [33]Satō Nobuhiko (佐藤 暢彦). Food poisoning statistical data: The occurrence of food poisoning 2019 [Excel format: 168KB] (食中毒統計資料: 令和元年(2019年)食中毒発生状況 [Excel形式:168KB]). Ministry of Health, Labour and Welfare, Tokyo (厚生労働省, 東京都). Source retrieved 3/4/2021

- [34]Miguel Bao, Graham J. Pierce, Santiago Pascual, Miguel González-Muñoz, Simonetta Mattiucci, Ivona Mladineo, Paolo Cipriani, Ivana Bušelić, Norval J. C. Strachan. Assessing the risk of an emerging zoonosis of worldwide concern: anisakiasis. Scientific Reports 7 (1). DOI: 10.1038/srep43699.

- [35]Tokyo Food Safety Information Center » Good things to know » Food parasites » Anisakis – Nematode. Bureau of Social Welfare and Public Health (東京都福祉保健局), Tokyo. Source retrieved 3/2/2021

- [36]食中毒の原因食品となったメジマグロにおけるアニサキスの寄生状況 (第29巻、10号) (Anisakis Parasitism in Bigeye Tuna as a Cause of Food Poisoning, (Vol. 29, No. 10)). Tokyo Metropolitan Institute of Public Health, Tokyo (東京都感染症情報センター, 東京)、 2008. Source retrieved 3/2/2021

- [37]Mladineo, I; Poljak, V.. Ecology and genetic structure of zoonotic anisakis spp. from adriatic commercial fish species. Applied and Environmental Microbiology 80 (4) 1281-1290. 2014. DOI: 10.1128/aem.03561-13.

- [38]I. Vardić Smrzlić, D. Valić, D. Kapetanović, B. Kurtović & E. Teskeredžić. Molecular characterisation of Anisakidae larvae from fish in Adriatic Sea. Parasitology Research 111 2385–2391. 2012. DOI: 10.1007/s00436-012-3094-4.

- [39]I.Mladineo, T.Šegvić, M.Petrić. Do captive conditions favor shedding of parasites in the reared Atlantic bluefin tuna (Thunnus thynnus)?. Parasitology International 60 (1) 25-33. 2011. DOI: 10.1016/j.parint.2010.09.007.

- [40]Jelena Žilić, Ivona Mladineo. Prevalence of the parasite Anisakis simplex (Anisakidae, Nematoda) in the blue fin tuna (Thunnus thynnus) from mariculture. MESO: The first Croatian Meat Journal 8 (4) 229-233. 2006

- [41]Jun Suzuki, Rie Murata, Yukihiro Kodo. Current Status of Anisakiasis and Anisakis Larvae in Tokyo, Japan. Food Saf (Tokyo) 9 (4). 2021. DOI: 10.14252/foodsafetyfscj.D-21-00004.

- [42]WHO Study Group on the Control of Foodborne Trematode Infections (1993 : Manila, Philippines) & World Health Organization. (1995). Control of foodborne trematode infections : report of a WHO study group. World Health Organization, Geneva. 1995

- [43]Food Facts: Fresh and Frozen Seafood Selecting and Serving It Safely. Food and Drug Administration, Silver Spring. 2015. Source retrieved 3/9/2021

- A. Eslami, H. Sabokroo, S. H. Ranjbar-Bahadori. Infection of Anisakids Larvae in Long Tail Tuna (Thunnus tonggol) In North Persian Gulf. Iranian Journal of Parasitology 6 (3) 96-100. 2011

- A. Huidobro, A. Pastor, M. Tejada. Quality Index Method Developed for Raw Gilthead Seabream (Sparus aurata). Journal of Food Science 65 (7). 2000. DOI: 10.1111/j.1365-2621.2000.tb10265.x.

- Arne Levsen, Bjørn Tore Lunestad, Björn Berland. Low Detection Efficiency of Candling as a Commonly Recommended Inspection Method for Nematode Larvae in the Flesh of Pelagic Fish. Journal of Food Protection 68 (4). 2005. DOI: 10.4315/0362-028X-68.4.828.

- Azusa Umehara, Yasushi Kawakami, Jun Araki, Akihiko Uchida. Molecular identification of the etiological agent of the human anisakiasis in Japan. Parasitology International 56 211-215. 2007. DOI: 10.1016/j.parint.2007.02.005.

- Bárbara Cavaleiro, Margarida Hermida, Aurélia Saraiva. Seasonal differences in parasite infection of skipjack tuna in Madeira archipelago. IMMR'18, International Meeting on Marine Research 2018, frontiersin.org, Frontiers Media, Lausanne, 2019-01-07. Source retrieved 3/4/2021

- Barbara Lund, Anthony C. Baird-Parker, Tony C. Baird-Parker, Grahame W. Gould, Grahame Warwick Gould. Microbiological Safety and Quality of Food - Volume I. Springer Science & Business Media. 2000

- Carlos Alberto M. Lima dos Santos. The storage of tropical fish in ice - A review. Tropical Science 23 (2) 97-127. 1977

- Evan A. Fiorenza, Catrin A. Wendt, Katie A. Dobkowski, Teri L. King, Marguerite Pappaionou, Peter Rabinowitz, Jameal F. Samhouri, Chelsea L. Wood. It’s a wormy world: Meta‐analysis reveals several decades of change in the global abundance of the parasitic nematodes Anisakis spp. and Pseudoterranova spp. in marine fishes and invertebrates. Global Change Biology 26 (5). 2020. DOI: 10.1111/gcb.15048.

- Food Safety and Inspection Service. Freezing and Food Safety. United States Department of Agriculture, 2013-06-15. Source retrieved 3/2/2021

- Joseph G. Sebranek, Lester E. Jeremiah. Freezing Effects on Food Quality, Chapter 3: Poultry and Poultry Products. CRC Press, Boca Raton. 1996

- Lorenzo Polimeno, Maria Teresa Lisanti, Margherita Rossini, Edoardo Giacovazzo, Lucrezia Polimeno, Lucantonio Debellis, Andrea Ballini, Skender Topi, Luigi Santacroce. Anisakis Allergy: Is Aquacultured Fish a Safe and Alternative Food to Wild-Capture Fisheries for Anisakis simplex- Sensitized Patients?. Biology 10 (2). 2026

- María Llarena-Reino, Ángel F. González, Carlos Vello , Luis Outeiriño, Santiago Pascual. The accuracy of visual inspection for preventing risk of Anisakis spp. infection in unprocessed fish. Food Control 23 (1) 54-58. 2012

- Marı́a Teresa Audicana, Ignacio J. Ansotegui, Luis Fernández de Corres, Malcolm W. Kennedy. Anisakis simplex: dangerous — dead and alive?. Trends in Parasitology 18 (1) 20-25. 2002. DOI: 10.1016/S1471-4922(01)02152-3.

- McKerrow J. H., Sakanari J., Deardorff T. L.. Anisakiasis: Revenge of the Sushi Parasite. The New England Journal of Medicine 319 (8) 1228-1229. 1988. DOI: 10.1056/nejm198811033191819.

- Mohammad Shafiur Rahman, Jorge F. Velez-Ruiz. Handbook of Food Preservation (ed. Rahman), Chapter 26: Food Preservation by Freezing. CRC-Press, Boca Raton. 2007

- Ole Mouritsen, Klavs Styrbæk, Mariela Johansen. Umami: Unlocking the Secrets of the Fifth Taste. Columbia University Press, New York. 2014

- R.M. George. Freezing proceseses used in the food industry. Trends in Food Science & Technology 4 (5) 134-138. 1993. DOI: 10.1016/0924-2244(93)90032-6.

- S. Jonsdottir. Quality index method and TQM system. In: Quality Issues in the Fish Industry (eds. Olafsson, Ingthorsson). The Research Liaison Office, University of Iceland. 1992

- Sabine Mierke-Klemeyer, Reinhard Schubring, Jörg Oehlenschläger. Veränderungen sensorischer und instrumenteller Parameter während der Gefrierlagerung von Ostseedorsch (Gadus morhua) bei unterschiedlichen Temperaturen (Changes in sensory and instrumental parameters during freeze storage of Baltic cod (Gadus morhua) at different temperatures.). Informationen für die Fischwirtschaft aus der Fischereiforschung 50 (4) 166-180. 2003

- The European Parliament And The Council Of The European Union. Regulation (ec) No 853/2004 Of The European Parliament And Of The Council of 29 April 2004, Laying down specific hygiene rules for on the hygiene of foodstuffs, The European Parliament And The Council Of The European Union. The Publications Office of the European Union, Luxembourg. 2004. Source retrieved 12/26/2020

- William Schafer, Suzanne Driessen. The science of freezing foods. University of Minnesota Extension, Minneapolis, 2018. Source retrieved 3/2/2021

- Y. G. Moharram, S. D. Rofael. Shelf life studies of foods and beverages : chemical, biological, physical and nutritional aspects (G. Charalambous, ed.), Chapter: Shelf life of frozen vegetables. Elsevier Science Publishers, Amsterdam

- 海の幸を安全に楽しむために ~アニサキス症の予防~ (To enjoy seafood safely - Prevention of anisakiasis). 農林水産省, Nōrin-suisan-shō (Ministry of Agriculture, Forestry and Fisheries)、 2022-09-20. Source retrieved 2/12/2024